Automation and intelligent technology is slowly changing the world of work across a vast range of industries. Catering businesses and restaurants are no exception to this phenomenon, and the prevalence of technology both at front of house and in the kitchen is undeniable.

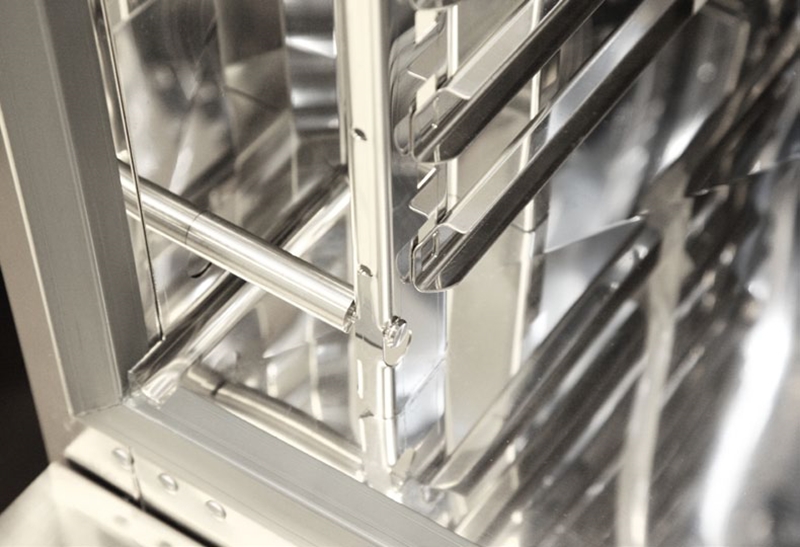

French company Friginox has revolutionised the way businesses think about commercial refrigeration, not just for preserving produce, but for innovative, exciting desserts. Part of the brand’s success is the dedication to excellence and attention to how the smallest details can enhance performance.

We’re taking a look at Friginox’s i-Chilling function and how it can benefit your establishment.

In the pursuit of the perfect freeze

Unlike other products which have a standard manufacturer temperature setting, the Friginox range of blast chillers and blast freezers are able to adapt their temperature to match the product being cooled. Whether you need a light chill or a fast, potent freeze, Friginox’s i-Chilling products can work in a range of 0-40 degrees Celsius.

The way it achieves this is by automatically adjusting settings depending on the product. Not only is this a more efficient option for a busy kitchen, it also means less guess work and better results.

As the company explains, at most, regular blast freezers or chillers can change the cooling air preset to an alternative temperature of about zero degrees C, restricting the flexibility and utility of the appliance.

The adaptive Friginox method was originally set in motion 20 years ago to change this, introducing a four-sensor probe which enabled more precise refrigeration. In addition, Friginox created a function where once a product’s core temperature reaches 15 degrees C or higher, the fixed air cooling temperature switching automatically from -20 to 0 degrees C.

Combined, these groundbreaking innovations mean that you can avoid undesirable ice forming on your produce that could otherwise compromise its integrity.

Fitting out your kitchen with Friginox

The multi-point core probe actively gathers data to determine the best possible settings for your blast chiller or freezer, so your products can reach their optimum temperature within food safety requirements.

By analysing product weight, quantity and consistency, your Friginox blast chiller can detect product behaviour throughout the freezing cycle. This means your staff can spend more time focusing on cooking and less time messing around with settings.

The best news is that all of Friginox’s models come with Self Adaptive i-Chilling as standard. When you buy your new blast freezer or chiller from Moffat, you know you’re equipping your kitchen with cutting edge technology.

Previous Article

A Midas Touch - Hellenika & The Fish House

0 Comments

Leave a reply

You must be logged in to post a comment.